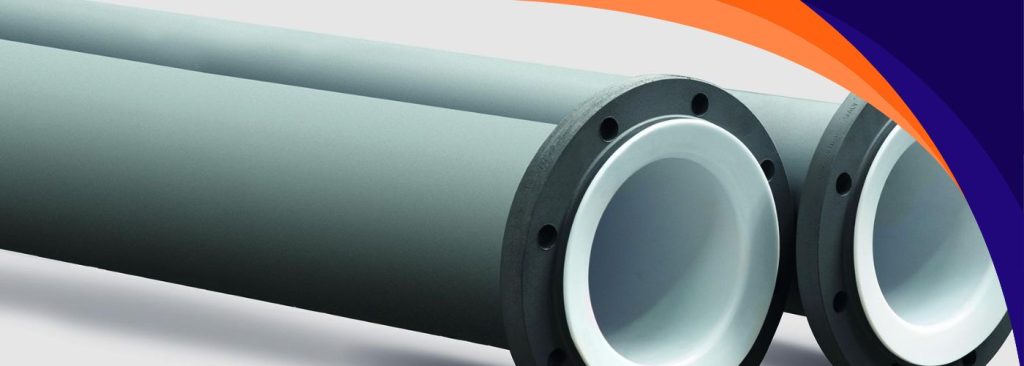

Leading the industry in Midland, UK, we are experts in producing high-performance PTFE, FEP, and PFA lined pipe spools and flanged pipe spools. Pipe spool is an in-factory fabricated section of a piping system constructed from pipes, flanges, and fittings combined into an installation-ready assembly. It allows for simple on-site installation and reduces construction time. Lined spools, especially PTFE-lined, offer high corrosion resistance, chemical inertness, and smooth flow, hence ideal for dealing with aggressive media. Advantages include reduced maintenance, increased service life, and compatibility with large quantities of chemicals.

A PTFE-lined pipe spool refers to a section of piping provided with an inner lining of Polytetrafluoroethylene (PTFE), a highly inert and non-reactive fluoropolymer. It possesses steel-like mechanical strength and PTFE-like chemical resistance, enabling it to carry corrosive or toxic chemicals. The PTFE lining is resistant to corrosion from metals, has smooth flow of the fluid and is also resistant to high temperatures and aggressive media. These spools are pre-assembled and are easily installed, and they are used extensively in industries like pharmaceuticals, petrochemicals, chemicals and water treatment where corrosion resistance and purity are of paramount importance. They enable system life extension as well as minimized maintenance requirements.

Grayson PTFE Lined Pipe is a leading supplier of PTFE Lined Pipe spool in Midland, UK, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| Nominal Bore | Internal Dia. (d) | PTFE Liner Thickness (t) | FLANGE P. C. D | Flange Hole Dia. | Raised | Max.Length | Pipe Schedule | |

|---|---|---|---|---|---|---|---|---|

| mm | Inches | (± 1 mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 25 | 1 | 19.5 | 3.3 | 79.4 | 15.9 | 51 | 3000 | 40 |

| 40 | 1.5 | 33.8 | 3.3 | 98.4 | 15.9 | 73 | 3000 | 40 |

| 50 | 2 | 45.4 | 3.3 | 120.6 | 19.0 | 92 | 3000 | 40 |

| 80 | 3 | 70.8 | 3.3 | 152.4 | 19.0 | 127 | 3000 | 40 |

| 100 | 4 | 95.2 | 3.8 | 190.5 | 19.0 | 157 | 3000 | 40 |

| 150 | 6 | 145.1 | 4.5 | 241.3 | 22.2 | 216 | 3000 | 40 |

| 200 | 8 | 197.4 | 5.0 | 298.4 | 22.2 | 270 | 3000 | 30 |

| 250 | 10 | 249.3 | 6.0 | 362.0 | 25.4 | 324 | 3000 | 30 |

| 250 | 10 | 249.3 | 6.0 | 362.0 | 25.4 | 324 | 3000 | 30 |

| 300 | 12 | 300.1 | 6.0 | 431.8 | 25.4 | 381 | 3000 | 30 |

PTFE lining protects the pipe spool from highly corrosive chemicals, acids, and solvents, extending the system’s lifespan.

Reduces friction, prevents buildup, and ensures consistent flow of media, even with sticky or aggressive substances.

Performs reliably under a broad range of temperatures and pressures without degrading or reacting.

Minimizes the need for frequent inspections, repairs, and replacements, lowering operating costs.

Yes, they are highly durable, offering long-lasting protection against corrosion and wear.

They offer outstanding chemical resistance and thermal stability, making them ideal for transporting aggressive and corrosive fluids.

The linings are either extruded or molded onto the metal surface, creating a secure bond and consistent, uniform protection throughout the pipe.

Yes, PFA can withstand up to 260°C (500°F), while PTFE and FEP are also heat-resistant.

They work with most chemicals but may not be compatible with alkali metals or highly reactive substances

We are the leading Manufacturer and Supplier of Grayson PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Midland, UK.